Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

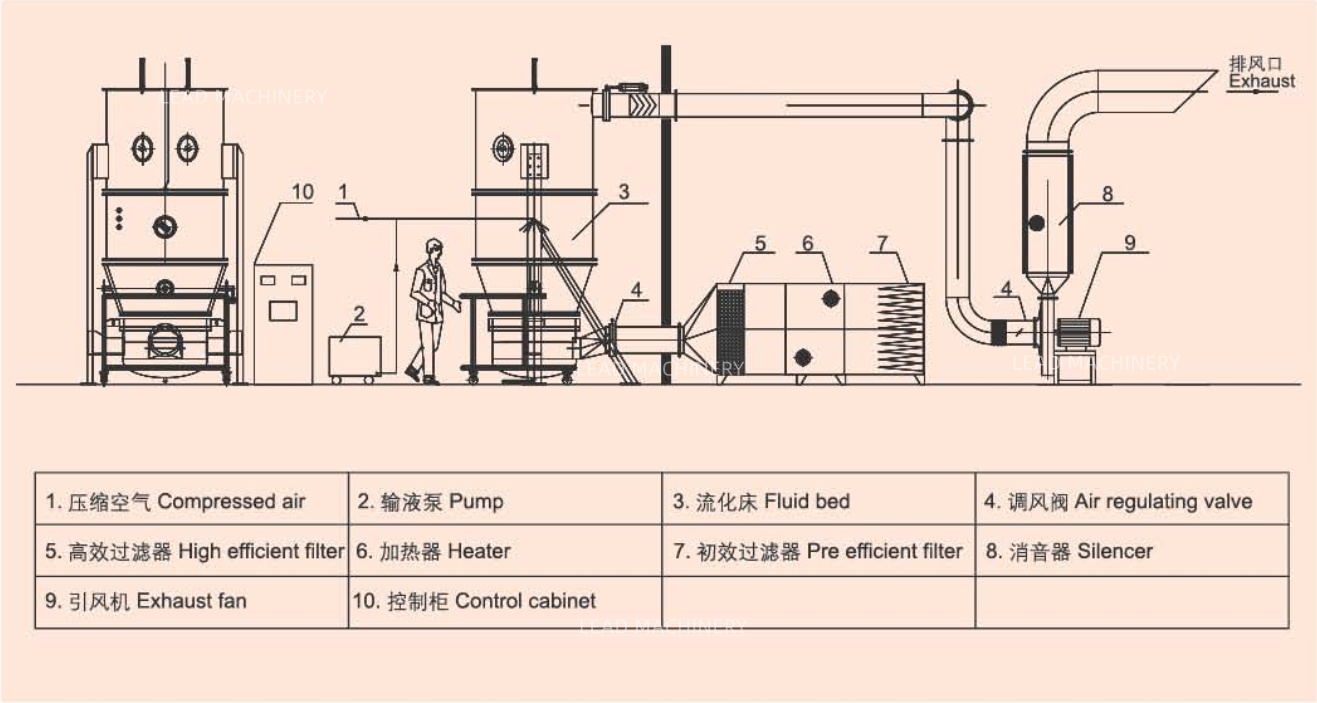

The ability to control key process parameters that directly impact these mechanisms is essential to successful granulation. In terms of air flow, these include the porosity of the distribution plate and the bed pressure drop, while for the granulation and drying process, critical factors are the inlet air temperature and relative humidity, solution spray rate, and atomization air pressure/flow. It is also important to consider exhaust air conditions and variables such as chamber pressure, fill volume, and filter pressure drop.

The size, density, porosity, strength, and compressibility of granules will all be controlled by these factors, along with flow properties, moisture content, and degradation. One of the most time-consuming stages of fluid bed granulation is drying, a step which can greatly impact the overall process efficiency.

Drying consists of three phases. Phase 1 occurs as the product bed and equipment warm up, during which surface water is removed at an increasing rate. During phase 2, a constant rate of surface water removal takes place, accompanied by the migration of small amounts of intra-granular water to the granule surface. Phase 3 involves the removal of bound water from the granule surface and is dictated by the rate of intra-granular water migration.

When implementing an effective fluid bed granulation process, it is important to determine acceptable final LOD limits or range and to identify upper temperature limits.

April 18, 2024

March 28, 2024

Email to this supplier

April 18, 2024

March 28, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.