Medicine fluidized bed granulator Powder granulating machine

$3000-4000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,Nanjing |

$3000-4000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,Nanjing |

Model No.: FL

Brand: Lead Macinery

Place Of Origin: China

Old And New: New

Machine Type: Granulator

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Core Component Warranty Period: 1 Year

Core Components: Plc, Pump, Motor

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Applicable Industry: Food &Amp; Beverage Factory, Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Viet Nam, Mexico, South Korea, Kazakhstan, Italy

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Germany, Pakistan, Argentina, Bangladesh, Tajikistan

Function: Granulating and drying

Application: Pharmaceutical, food and chemical

Size Of Granules: 40~100 meshes

Working Temperature: 60~120℃

Work Time: About 1.5h/ batch

Material: SUS304/ SUS316L

Heating Source: Steam/ Electricity

Control System: Touch screen / Button type

Explosion-proof: Custmized

Certificate: CE

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

1. General description of Fluid Bed Granulator

FL series Fluidized Bed Granulator is a batch type top spray powder granulation/ agglomeration processor which has been widely used in foodstuff, chemical, feedstuff, health products industry and so on.

It combines the functions of mixing, granulating and drying in one body, so it is also called one step granulator.

Granulation is a process of transforming the powder particles into ideal, uniform and porous spherical articles. The powdery particles are annulus fluidized in the material container of the fluidized Granulating Machine. Some particles form into pellets containing adhesives after being mixed and preheated by purified heating air and mixing with atomized binder solution. Being dehydrated by the hot air, the water evaporated from the pellets and the adhesives freeze.

Pictures of Fluid bed granulator

2. Application of Fluid bed granulator

FL fluidized bed granulator is widely used in producing tablet granules, granules and capsules granules in pharmaceutical industry and for cocoa, coffee, milk, juice of granule, and flavoring in food industry. Additionally, this fluidized granulating machine is suitable for palletizing in pesticides, fertilizer, pigment, dyestuff as well as coating granules, pill protecting layer, available colors, release, film and enteric.

Granules that made by fluid bed granulator

3. Features of Fluid bed granulator

1. FL fluidized drying granulator through powder granulation improves the mobility and solubility as well as reduces the flying dusts.

2. The mixing, granulation and drying can be completed in the same fluidized granulating machine.

3. The antistatic filter cloth is used to ensure the security of equipment operation.

4. This fluidized drying granulator adopts pressure relief holes to ensure the safety of the facility and staff in case of the explosion.

5. Our fluidized granulating machines are without any dead angle as well as easy to load and unload materials.

6. This granulating equipment is easy to wash, conforming to the GMP standard.

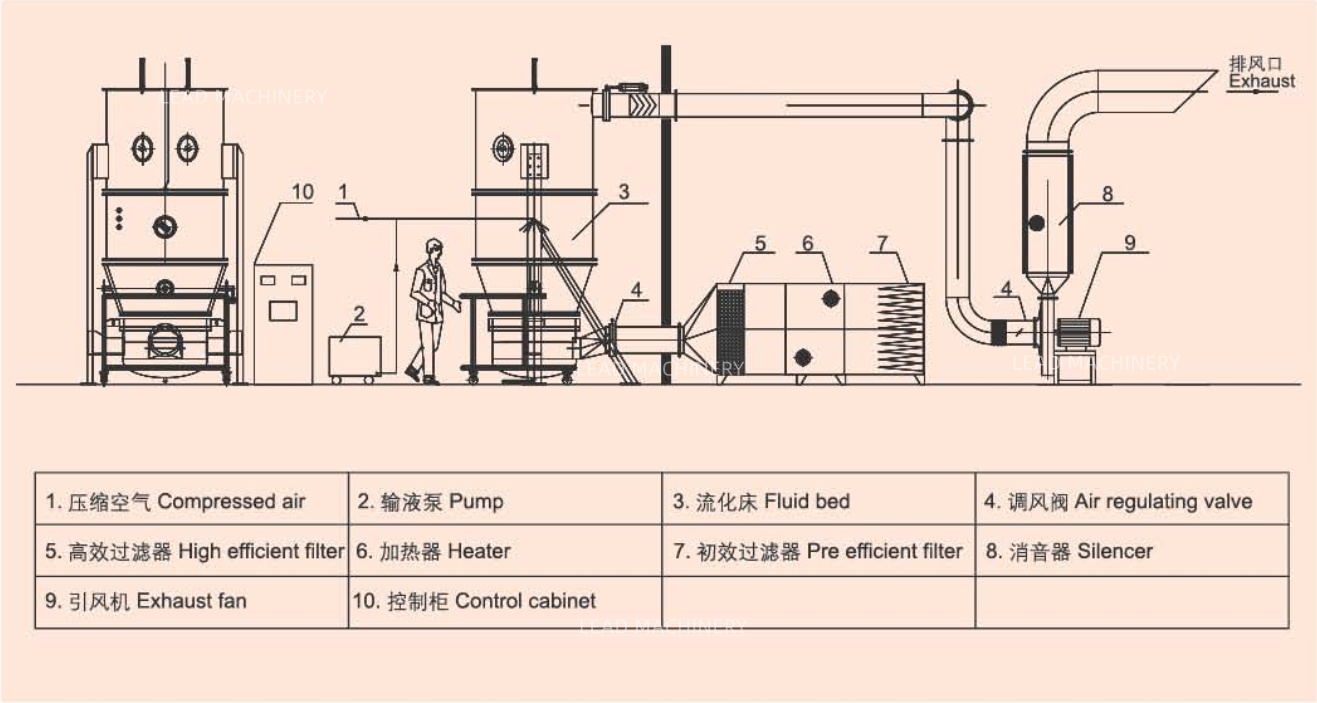

Flow chart of Fluid bed granulator

4. Technical advantages of Fluid bed granulator

4.1. cGMP Design: 150 grit exterior finish, mirror finish on internal surfaces. The system can meet GMP standard;

4.2. HEPA air filter: The air filter consists of primary stage, secondary stage and high efficiency stage air filter and the air cleanness can reach 100,000 grade;

4.3. Automatic pneumatic sealing: Two pneumatic cylinders lift the granulation bowl for sealing with the top chamber; the inflated square rubber ring will seal the bottom chamber to create a completely sealed granulation chamber;

4.4. Two-bag-filter-chamber system: The top bag filtering system has two chambers which work alternately to avoid air pressure onto the filter bag. The product rate can reach 99%.

4.5. Accurate air flow control: The exhaust fan is combined with inverter to accurately control the air flow rate for achieving perfect fluidization.

4.6. Good working condition: The whole system is working under negative pressure, so there is no powder leaking at all. Exhaust fan is equipped with silencer as well as isolated installation, the noise is below 75 dB(A).

4.7. Safety measures: The whole system adopts following measure to 100 % make sure safety during operation:

4. Parameters of Fluid bed granulator

| Model | FL-3 | FL-5 | FL-15 | FL-30 | FL-60 | FL-90 | FL-120 | FL-200 | FL-300 | FL-500 |

| Volume of container (L) | 12 | 22 | 45 | 100 | 220 | 300 | 420 | 670 | 1000 | 1500 |

| Capacity (kg/batch) | 3 | 5 | 15 | 30 | 60 | 100 | 120 | 200 | 300 | 500 |

| Power of fan (kg) | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 37 | 45 |

| Steam consumption (kg/h) | 15 | 23 | 42 | 70 | 141 | 180 | 211 | 282 | 366 | 451 |

| Pressure of steam (Mpa) | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 |

| Consumption of compressed air (m3/min) | 0.6 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.0 | 1.1 | 1.5 | 1.5 |

| Working temperature (℃) | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 | 40~120 |

| Working time (min/ batch) | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 | 45~90 |

| Product collecting rate | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% |

| Weight of machine (kg) | 500 | 700 | 900 | 1000 | 1100 | 1200 | 1300 | 1500 | 1800 | 2000 |

| Size of output granules (mesh) | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 | 40~100 |

| Moisture of output granules | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.