Continuous fluidized bed dryer Horizontal fluid bed dryer

$5000-100000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,Nanjing |

$5000-100000 /Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,Nanjing |

Model No.: XF

Brand: Lead machinery

Species: Fluid Bed Drying Equipment

Application: Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing

Old And New: New

Place Of Origin: China

Core Selling Point: High Productivity

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Food &Amp; Beverage Factory, Energy &Amp; Mining

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Viet Nam, Russia, South Korea, South Africa

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Viet Nam, Russia, Algeria, Nigeria

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Plc

Heat Source: Steam Heating

Material: Sus304, Sus316, Sus316l, Ti, Sus304l

Working Type: Continuous type

Input Material: Powder/ granules

Material: SUS304/ SUS316L/ Q235

Heating Source: Steam/ thermal oil/ electricity/ oil/ gas

Control System: Touch screen/ Button type

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

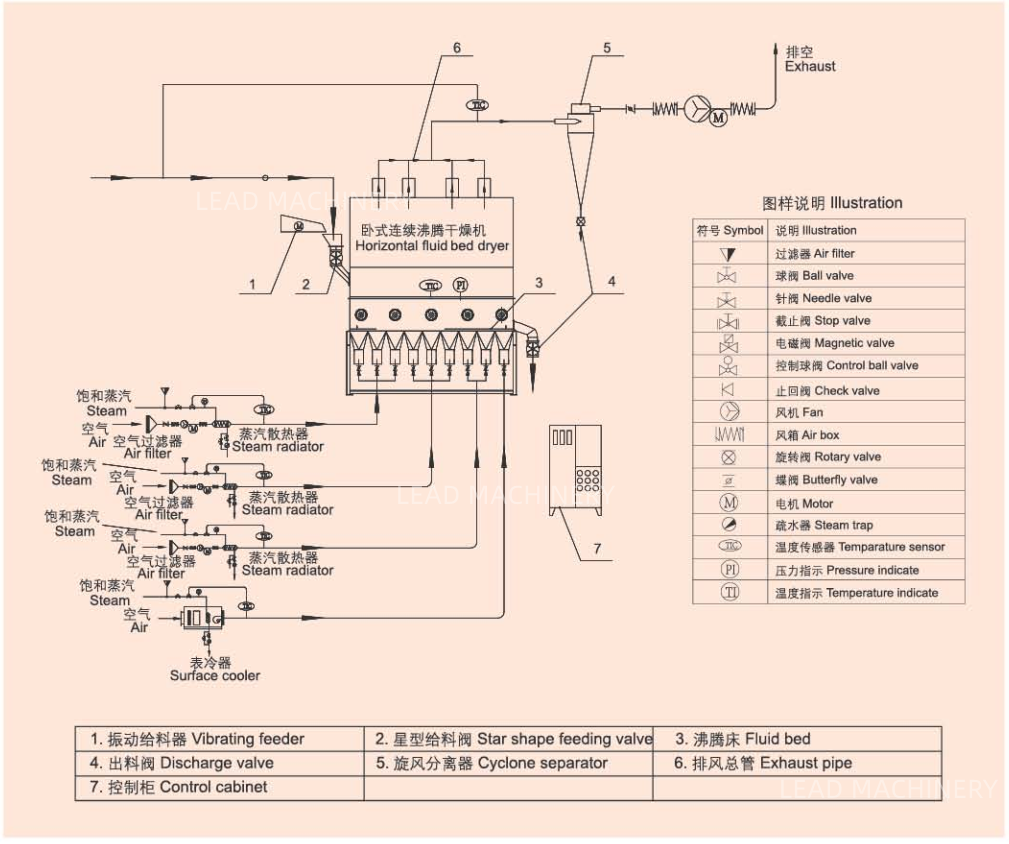

Continuous Horizontal Fluid Bed Dryer is also called as fluidized-bed. It consists of air filter , heater ,fluidized-bed main machine, feeder , cyclone separator , cloth bag duster (Optional) ,high-pressure centrifuge fan and air pipe ,control chest. Because the properties of raw materials exist difference, when equip the dust removing equipment, it should consider the practical need. It can select cyclone separator and cloth bag duster at the same time or one of them. In general, it needs to select cyclone separator only for raw material that is large in specific gravity and cloth bag duster for powder and small granule raw materials that is light in specific gravity .Meanwhile there is air feeding device (sending air fan) and belt conveyor for selection. Raw material is fed into fluidized-bed drier through feeder. Fresh air through filtering and heating is sent to the bottom of fluidized bed by fan and contacts with solid raw material on distributing plate. In this way the fluidized state is formed and the heat exchange between air and solid is carried out. The dried raw material is discharged from outlet and wasted gas is exhausted from the top of fluidized-bed where catches solid powder through cyclone separator , cloth bag duster. The heating way have different kinds to choice such as steam can be used (it can be supplied as client request).

The clean and hot air enters into fluidization bed through distributor of valve plate. The wet material fed from feeder will be

formed a fluidization state by hot air (jumping within the bed like boiling water), so it is called fluidizing dryer(or machine).Because of the large contacting area between hot air and materials, the drying time is short. The air enters from one end of bed, through" boiling" several minutes and then comes out automatically from the other end.

3. Technical parameters of Horizontal fluid bed dryer

| Model | XF0.25×1 | XF0.25×2 | XF0.25×3 | XF0.25×6 | XF0.3×2 | XF0.3×4 | XF0.3×6 | XF0.3×8 | XF0.3×10 | XF0.4×4 | XF0.4×6 |

| Drying area (m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| Evaporation capacity (kg/h) | 10~15 | 20~25 | 30~45 | 52~75 | 20~30 | 42~60 | 63~90 | 84~20 | 105~150 | 56~80 | 84~120 |

| Power of fan (kW) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| Inlet air temperature (℃) | 120~140 | ||||||||||

| Outlet air temperature (℃) | 40~60 | ||||||||||

| Size of main machine (mm) | 1×0.6×3.35 | 2×0.6×3.35 | 4×0.6×3.35 | 6×0.6×3.35 | 2×0.7×3.4 | 4×0.7×3.4 | 6×0.7×3.4 | 8×0.7×3.4 | 10×0.7×3.4 | 4×1×3.58 | 6×1×3.58 |

| Occupied area (m2) | 18 | 25 | 35 | 40 | 25 | 38 | 45 | 56 | 70 | 18 | 56 |

| Model | XF0.4×8 | XF0.4×10 | XF0.4×12 | XF0.5×4 | XF0.5×6 | XF0.5×8 | XF0.5×10 | XF0.5×12 | XF0.5×14 | XF0.5×16 | XF0.5×18 |

| Drying area (m2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| Evaporation capacity (kg/h) | 112~160 | 140~200 | 168~240 | 70~100 | 105~150 | 140~200 | 175~250 | 210~300 | 245~350 | 280~400 | 315~240 |

| Power of fan (kW) | 48 | 70 | 70 | 30 | 48 | 70 | 105 | 140 | 147 | 169 | 197 |

| Inlet air temperature (℃) | 120~140 | ||||||||||

| Outlet air temperature (℃) | 40~60 | ||||||||||

| Size of main machine (mm) | 8×1×3.58 | 10×1×3.58 | 12×1×3.58 | 4×1.2×4.1 | 6×1.2×4.1 | 8×1.2×4.1 | 10×1.2×4.1 | 12×1.2×4.1 | 14×1.2×4.1 | 16×1.2×4.1 | 18×1.2×4.1 |

| Occupied area (m2) | 74 | 82 | 96 | 50 | 70 | 82 | 100 | 140 | 180 | 225 | 268 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.